Repair method:

cleaning-treatment of delamination-cleaning-polishing-cleaning-anti-corrosion treatment.

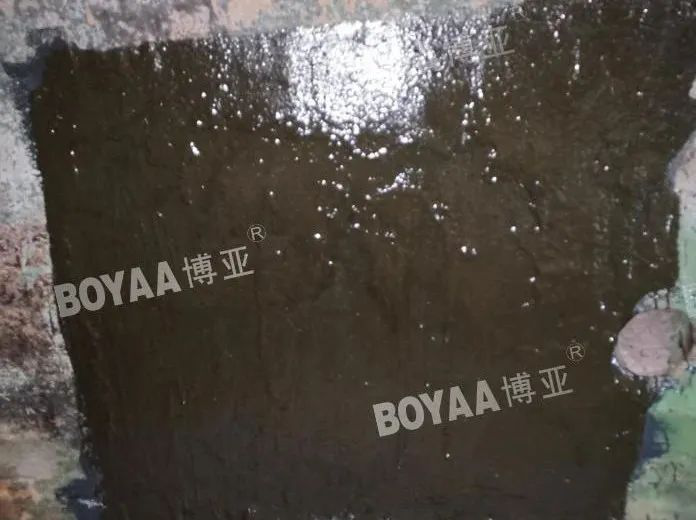

Before repair

Repairing

Process flow (BY55 BY20)

1、Eliminate all delamination parts of the anticorrosive glue. After shoveling clean, place it to dry. After the equipment is dry, use a steel wire ball to polish, and polish the connection between the delaminating and delamination. The oxide layer must be ground off and a fresh surface is ground.

2、 Clean the polished surface with BY55 oil cleaner (alcohol or thinner can also be used). After polishing, the surface will be clean, dry, oil-free and dust-free.

3. Use pure hand-brushed anti-corrosion: (it is recommended to repair the uneven surface, and then do anti-corrosion)

4、 Mix the high temperature wear-resistant anticorrosive BY20 evenly according to the mixing ratio in the instructions on the package (group A: group B mixes 5:1-8:1, depending on the on-site temperature), component A must be opened , Stir the contents evenly. Adjust too much at one time and be sure to mix well. After mixing evenly, add a small amount of diluent. (The maximum amount of diluent for a set of high-efficiency preservatives is less than 1 kg. It is not easy to add more. Adding more will weaken the performance of the original rubber. The main reason for adding the diluent is that the original rubber is thick, making it slightly Thin, easy to brush) for easy brushing, one-time thickness is about 0.3-5MM, (should be coated on a dry, clean, rough surface. The polymer material is further cross-linked into a network structure, which can significantly improve the overall coating Performance) The first painting must be done in place and everything must be done in place.

5、 Brush the anti-corrosion coating three times, the thickness is about 1mm;

First pass: use brushing method, brush 0.4mm, use horizontal brush;

Second time: use brushing method, brush 0.3mm, use vertical brush;

Third pass: use brushing method, brush 0.3mm, use horizontal brush.

THE END

Our company has always been committed to providing customers with high-quality products, while providing you with high-quality technical support and services, strong technical force, to escort the safe operation of your equipment. We will strive to do better.

If you have purchase, cooperation and other needs, you can get in touch with the editor and look forward to your call at any time!

You can contact our company through the following channels:

Phone: 0791-88210181

18170021086

Email: jxbooya@126.com

Looking forward to serving you! ! !

Scan and pay attention

Scan and pay attention

Wechat consulting

Wechat consulting